Executive Summary

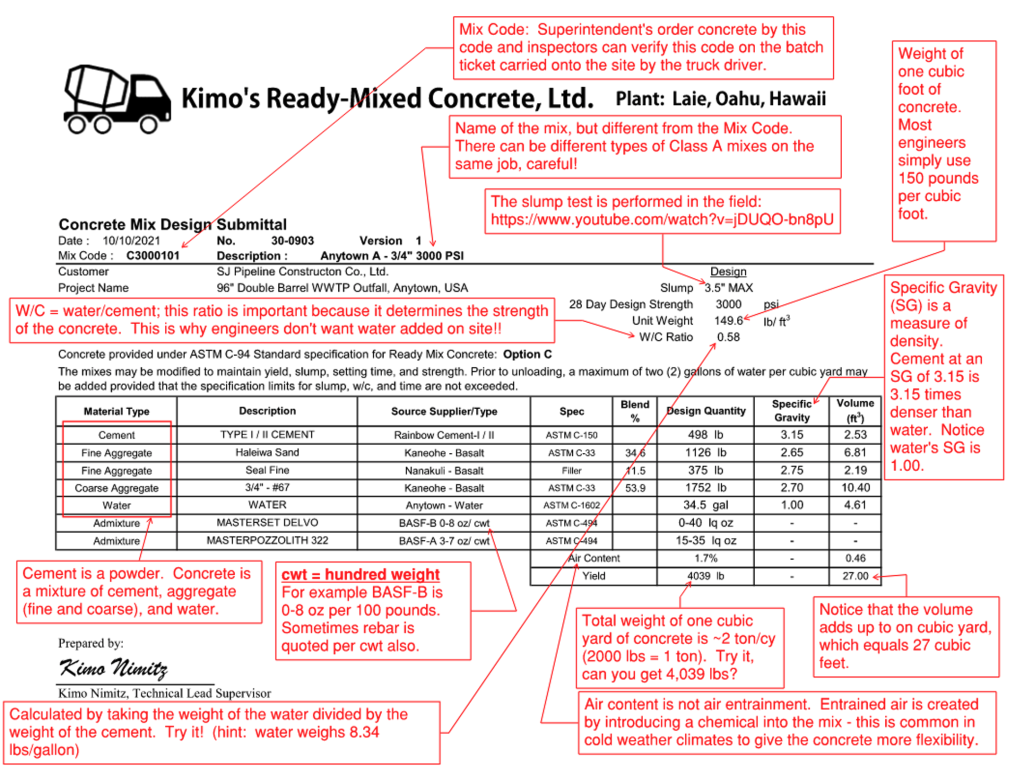

Knowing how to read a concrete mix design is helpful for the project management team: from project manager to foreman. Here are some basics.

What is concrete?

Concrete is arguably the most common construction material used on the globe. It is a mixture of cement, aggregate, and water. When these three ingredients are mixed together, the resulting material hardens after minutes or hours. This material can then withstand pressures in excess of 3,000 pounds per square inch (psi).

Aren’t there other ingredients?

Yes. Concrete can get very intricate. It’s an art to build a concrete mix – it’s similar to a cake in that you measure the ingredients and stir. Other ingredients include fiber for reinforcement, admixtures for workability, different aggregates (like lightweight aggregate to decrease the density), and even dye for electrical ductbank use. And many more!

How are concrete mixes designed?

Concrete plants employ technicians who design the concrete mixes. Most concrete has an overall requirement by Contract to achieve a certain strength – most times you will see in a specification that “concrete must have a x,xxx psi strength at 28 days”. This 28-day duration is the generally accepted time period for concrete to mature to its ultimate strength.

But concrete mix designers often have to design mixes which cater to the contractor. The technician must consider:

- Delivery method into the pour – for instance, if a concrete pump is being used, then admixtures and aggregate are selected to allow the concrete to physically get through the pump pipe.

- Aggregate size – if concrete is going in a heavily reinforced structure, then aggregate is usually chosen to be as small as possible, so it fits between the rebar.

- Workability – concrete finishers on pour day usually want a creamy, wet mix so finishing the concrete is easier – this can be improved by the addition of admixtures.

My Story

The attached concrete mix design was a submittal (names changed to protect the innocent) on a recent project of mine. I don’t pay much attention to them frankly; I trust the technician. But if you are a contractor, your superintendent and his/her finishers will certainly have an opinion. And if you’re an inspector, concentrate on the Mix Code. There may be three 4,000 psi concrete mixes on the job. Don’t confirm the correct mix by the description of the mix, use the Mix Code. Same holds for superintendents, don’t just say “bring me the 4,000 mix”, use the Mix Code.

Work Safe!

0 Comments