The SJCC Process

We Assess Your Need

Whether you are a contractor, owner, engineer, architect, or attorney, we seek first to understand your needs and then to provide recommendations and solutions.

We Do the Hard Work

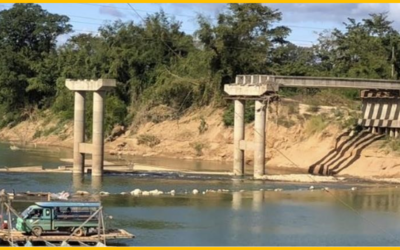

Our decades of experience in heavy and civil construction include roadway, WWTP, bridge, WWPS, utility, environmental, and building in both the public and private sectors. We’ve worked on all sizes of projects from small change orders to contracts as large as $5 billion.

You Enjoy the Results

Benefit from our specialized background in construction and engineering. Our team’s experience and education creates maximum value.

We Follow The 3 C’s Too!

If you’re a bonded contractor, you know you got there by adhering to the 3 C’s – character, capacity, and capital. We do too. Give us a call, we’re here to help!

Services

What We Do Best

Contractor Claim Support

- Entitlement evaluation

- Productivity analysis

- Quantum calculation

- Time impact analysis

Scheduling

- Project Scheduling

- Baseline development

- Monthly updates

- Submittal creation & review

- Time impact analysis

- Full technical narrative development

Construction Management

- Submittal/RFI management

- Change management/negotiation

- Value engineering

- Design/build assistance

- Schedule analysis

Expert & Forensic Work

- Construction claims – means & methods, constructability, productivity, schedule, cost, design E&O

- Insurance claims – rain, wind, earthquake, settlement

Cost Estimating

Commercial, public sector and private

- Pre-construction budgetary

- Active construction independent cost estimates

- Contractor hard bids

Taking the guesswork and risk out of job costing, so you can focus on the work.

Professional Engineering

The expertise and confidence to stamp items “traditional’ engineers will not, such as

- Thrust blocking

- Rigging

- Traffic control

- Formwork

Currently registered in ten states and Puerto Rico.

Contractor Licensing

Whether you’re crunched for time or just not computer-savvy, we help with all aspects of contractor license acquisition. We’re also a Contractor/RME “matchmaker”!

Candidate Placement

Need assistance finding the right people to build your dream team? Reach out now, we’d love to help. As a give-back to our industry, we encourage you to leverage our robust network of top professionals in the field today.

Why SJ Construction Consulting, LLC

Expertise

Decades of experience in heavy/civil, WWTP, WWPS, site, utility, bridge/roadway, and environmental work.

Responsiveness

If you call (833) SJ-CIVIL, we’ll contact you back within 4 minutes or 4 hours. Otherwise call or text our CEO at (808) 271-5150.

Resources

HCSS HeavyBid, EquipmentWatch Bluebook, Smartsheet, Revu Bluebeam, and an exclusive international list of professionals. We have the tools and contacts to directly help you, or get you to someone who can.

Decades of experience in heavy and civil construction, including roadway, WWTP, bridge, WWPS, utility, environmental, and building in both the public and private sectors. We work on projects from small change orders up to contract values of $5 billion.

We have a unique background in that our company is guided by former contractors who possess appropriate education and certifications to maximize our value to clients.

We provide pre-construction, estimating, construction management, claims, legal, surety assistance, professional services, and training.

Latest From The Podcast

Increase Profit by Rule of 27

Executive Summary. Most decisions can be further analyzed by collaborative or self-inquiry. When looking for ways to decrease costs, ask yourself...

Data Collection Without the $100,000 Fancy Toys

Executive Summary. Collecting data from a construction jobsite can serve many purposes, and all of them very beneficial. Uses such as claim...

Two Negatives of Owning Your Own Construction Business

Executive Summary. Owning your own construction business, or any business for that matter, is not all Porsches and Rolexes. It can be a lonely and...

Red Flags in Bid Day v. Change Order Pricing

Executive Summary. The difference between bid day pricing and change order pricing is miles apart because of one factor. Learn this factor and...

How to Make a Submittal – Check, Check, Check!

Executive Summary. Making submittals on a construction project is art and science. Increase your success rate on submittals using this method!...

Common Rebar Inspection Fails

Executive Summary. Learn here the what-not-to-dos of rebar installation. Some photos of fails here will certainly affect your pour schedule – and...

Our Clients

Our Clients

We deal regularly with many firms from the ENR Top 15 list to those that wish they could just break into ENR’s Top 400. Conractors, engineers, attorneys, and the owners of these projects.

Client Reviews

Over fifty (50) letters from clients, plus testimonials below – SJ Construction Consulting, LLC has earned its fantastic reputation from quality work provided to great clients.