Executive Summary: One of the most basic properties of a beam is its section modulus. How does the section modulus, S, come into play in structural design? And, why should I care?

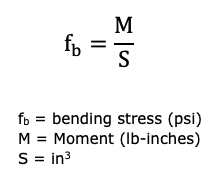

What is a beam? Keeping it simple here, a beam is a horizontal member supported at two ends. When you stand in the middle of the beam, it bends. When the weight in the middle of the beam is too great, the beam will break, or fail. The failure of this beam is calculated by one very simple equation:

Quick example. Go out to your driveway and set two cinder blocks 10’ apart. Then go get a 2×6 piece of lumber and lay it on the flat on these two blocks. You now have what is known in the structural engineering world as a simply supported beam 10’ long. Now stand in the middle of the board. Let’s assume you weight 200 lbs. Here’s what we got using the above formula:

fb= bending stress (we don’t know it, let’s solve for it)

M = P*L / 4 = 200 lbs * 120 inches / 4 = 6,000 lb-inches

S = bh2/ 6 = 5.5 inches * 1.5 inches * 1.5 inches / 6 = 2.0625 in3

[ Moment, M, can be found anywhere on the web, see http://www-classes.usc.edu/engr/ce/457/moment_table.pdfwhich provides an excerpt from the American Institute of Steel Construction – see condition 7. Simple Beam – Concentrated Load at Center] [ Section modulus, S, can be found anywhere on the web, see Wikipedia at https://en.wikipedia.org/wiki/Section_modulusand look at Rectangle ]It follows that the stress in the beam is

fb (calculated from above)= 6,000 lb-inches / 2.0625 in3= 2,909 psi

fb (allowable) = 2,100 psi (assuming Southern Pine, Select Structural)

[ fb (allowable)was taken from Table 1 at https://www.southernpine.com/using-southern-pine/design-values/ ]Does the beam fail? Yes, it does, since the calculated stress in the beam is 2,909 psi and the allowable stress is only 2,100 psi. 2,909 psi is greater than 2,100 psi.

The short disclaimer. There are many factors which go into the allowable stress of timber. You will notice these many variables on the sheet you were referred to above www.southernpine.com(see Ft, Fv, etc.). There also would have to be some better fixation of the beam at the cinder blocks, to truly model this behavior. This example is provided to give an elementary introduction of beam design.

How do I use this information? You use it when you talk to your shoring engineer, your temporary structure engineer, or your in-house staff when you’re trying to buy lumber, structural steel, or sheet pile. You also use it when talking to your client or the engineer of record about structural issues. Having this knowledge imparts confidence in the client that you’re competent as well as sends a message to the engineer of record that you know enough about his/her work to keep an eye on him/her.

My Story. The section modulus is a number. It’s a property of a shape – virtually any shape. It has nothing to do with timber, stainless steel, aluminum, plastic, or your standard structural steel. It’s just math. Look at its units – cubic inches. That makes no sense, right?

However, you see in the calculation that in order to size a beam appropriately, the section modulus, S, is a critical variable. And really, only one of two variables in structural design (the other variable being moment, M).

I had a project once where we had to install sheet piles and the contract specified a sheet pile thickness. The section modulus, S, was way more than we needed to resist the lateral load from the adjacent building and its soil. But we bid it with this sheet pile anyway.

Before reading any further, think about how a sheet pile resists load, it’s a beam just standing vertically. The sheet pile is installed vertically in the ground and it is put into bending by the soil acting horizontally. We are concerned about the sheet pile failing in bending from lateral load, so we’re right back to the allowable bending stress of the sheet pile when it’s behaving as a vertical beam.

When it came time to build the job, we determined that the load on the sheet piles needed a much smaller section modulus, S. We chose a smaller sheet pile which saved us a lot of money and still had the needed structural strength to resist the load.

0 Comments